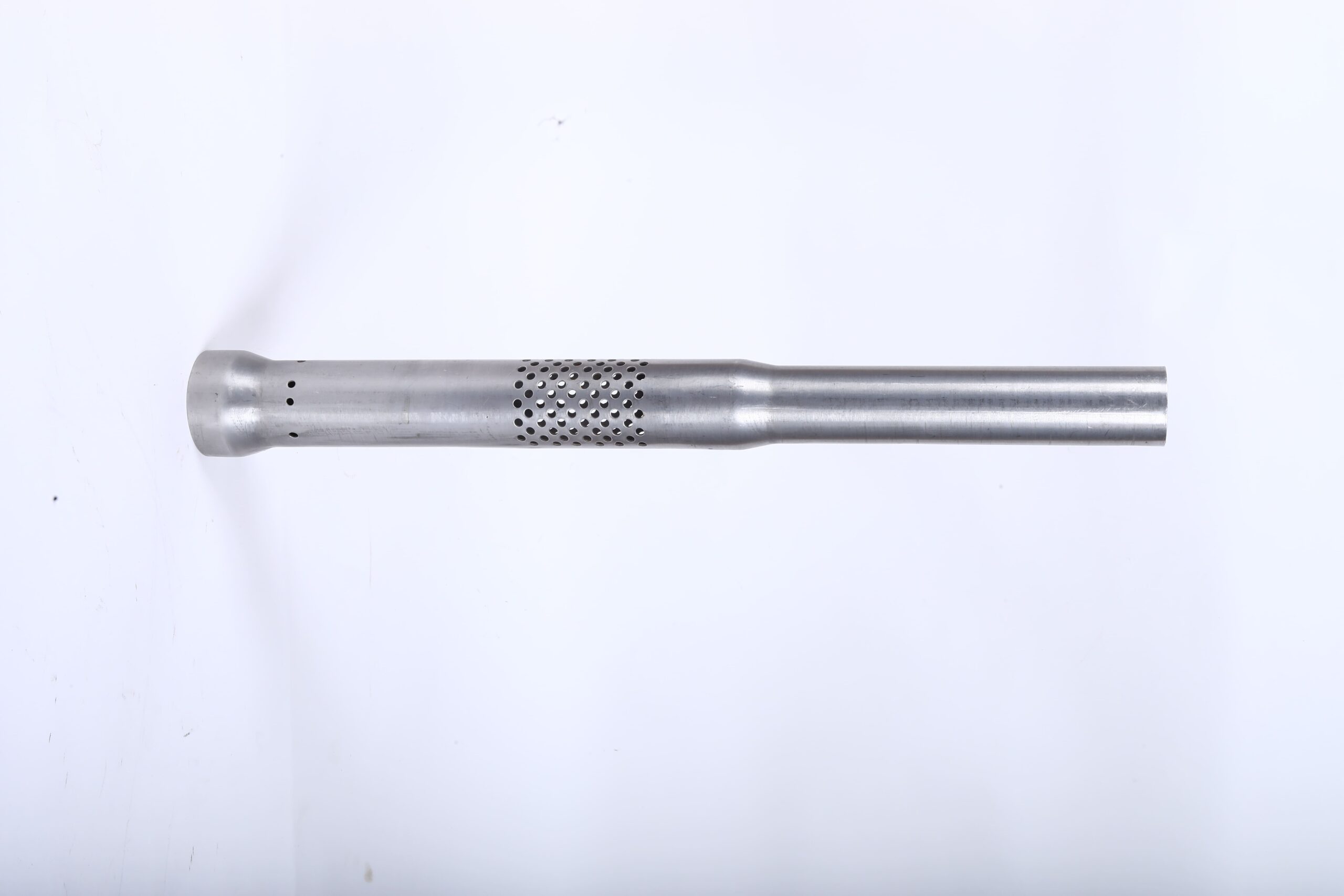

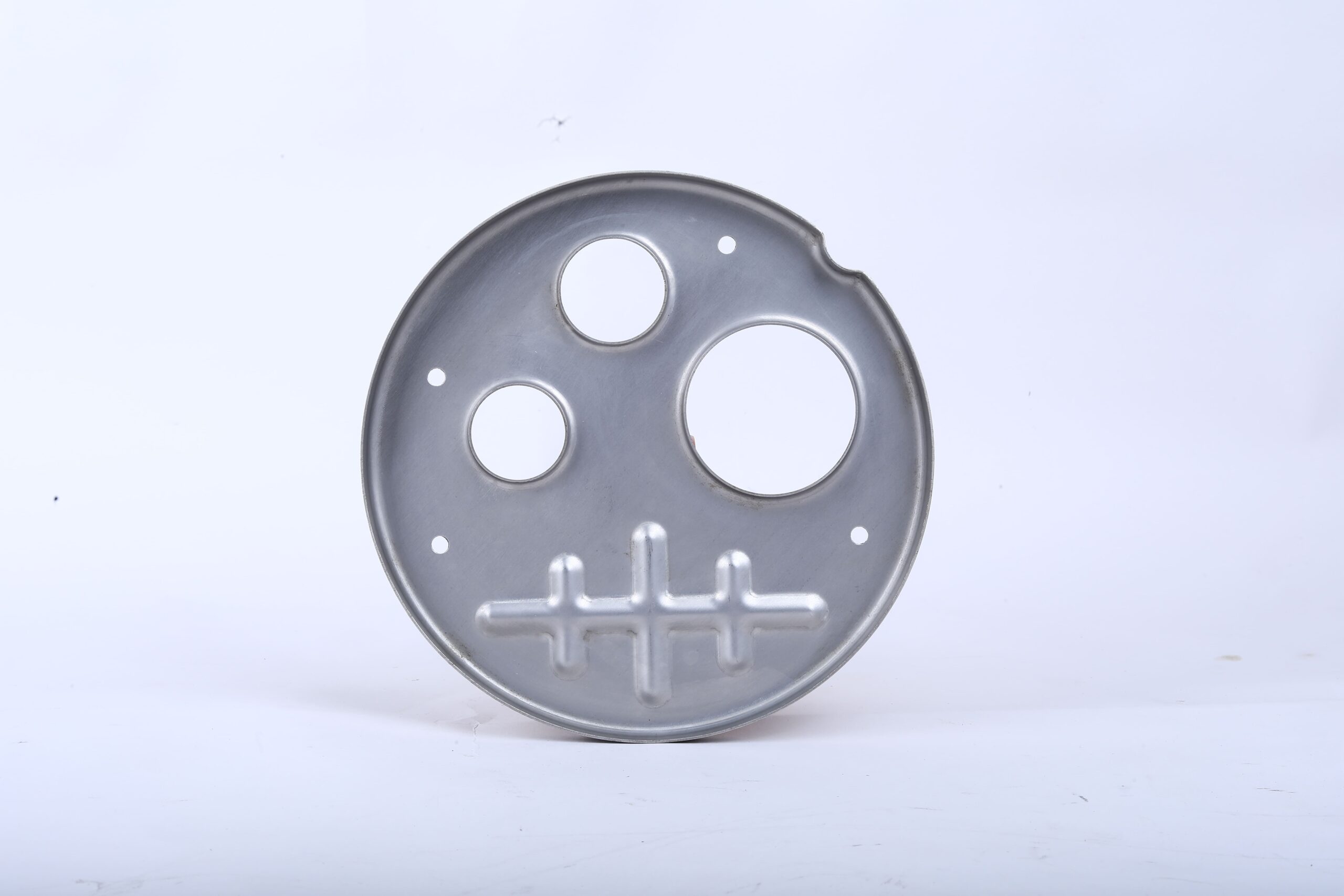

Fujin Automotive has demonstrated its unparalleled ability to design metal four-wheeler body parts. The business is renowned for providing its clients with precision stainless steel parts that are small, light, robust, and low-friction. The company places a high priority on allocating a significant portion of its resources to research and development in order to guarantee that they have the most advanced technology for metal fabrications.

Automotive Parts 4-wheeler

We at FUJIN Automotive are a top manufacturer and supplier of high-precision metal body four-wheeler parts in India, having been among the first to develop sheet metal running boards and tow hooks for tractor forms. We can meet all OEM sourcing requirements for parts because we have end-to-end capabilities. The following are some of the main areas in which we specialize:

Being one of the top producers and suppliers of electric motor parts for four-wheeler chassis, we have top-notch infrastructure and domain knowledge. Our baseline design approach is driven by our initial 3D designs combined with CAE analysis technologies, which allows us to build products that are minimally sized, lightweight, strong, long-lasting, high-performing, and extremely low in friction. In addition, we have been continuously allocating a major amount of resources for thorough research and development in order to create a range of “first-on-the-market” parts and components for the four-wheeler sector.

Utilizing the most up-to-date tools and equipment, the staff members assigned to the designing bay consistently maintain their attention on the precise needs of the clients. In addition to identifying every conceivable location where costs may be reduced, they also suggest appropriate substitute materials for the successful and efficient geometry optimization of the parts that clients require. Most of the time, we use 3D modeling techniques to optimize designs with the goal of reducing labor and production costs as well as material requirements.

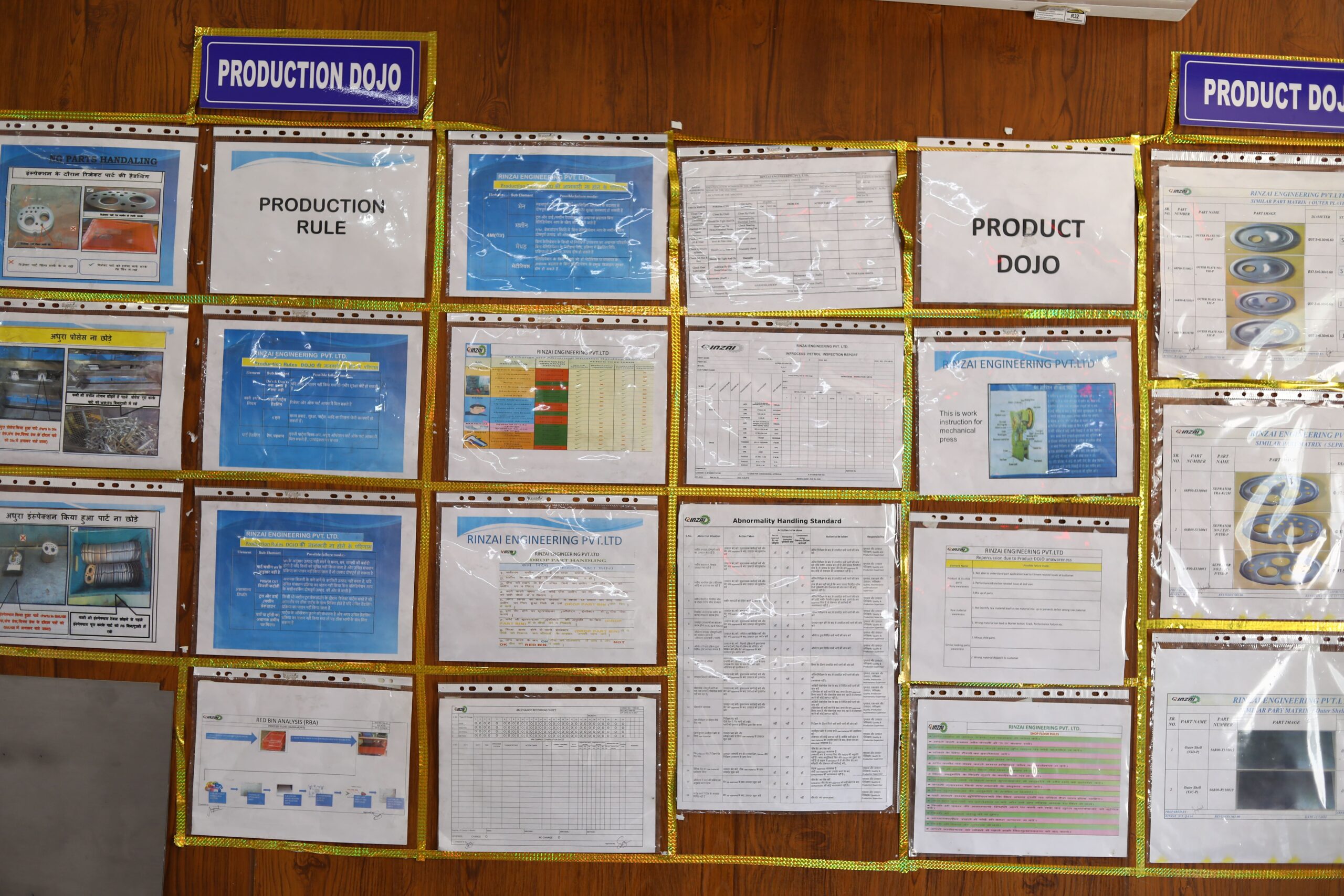

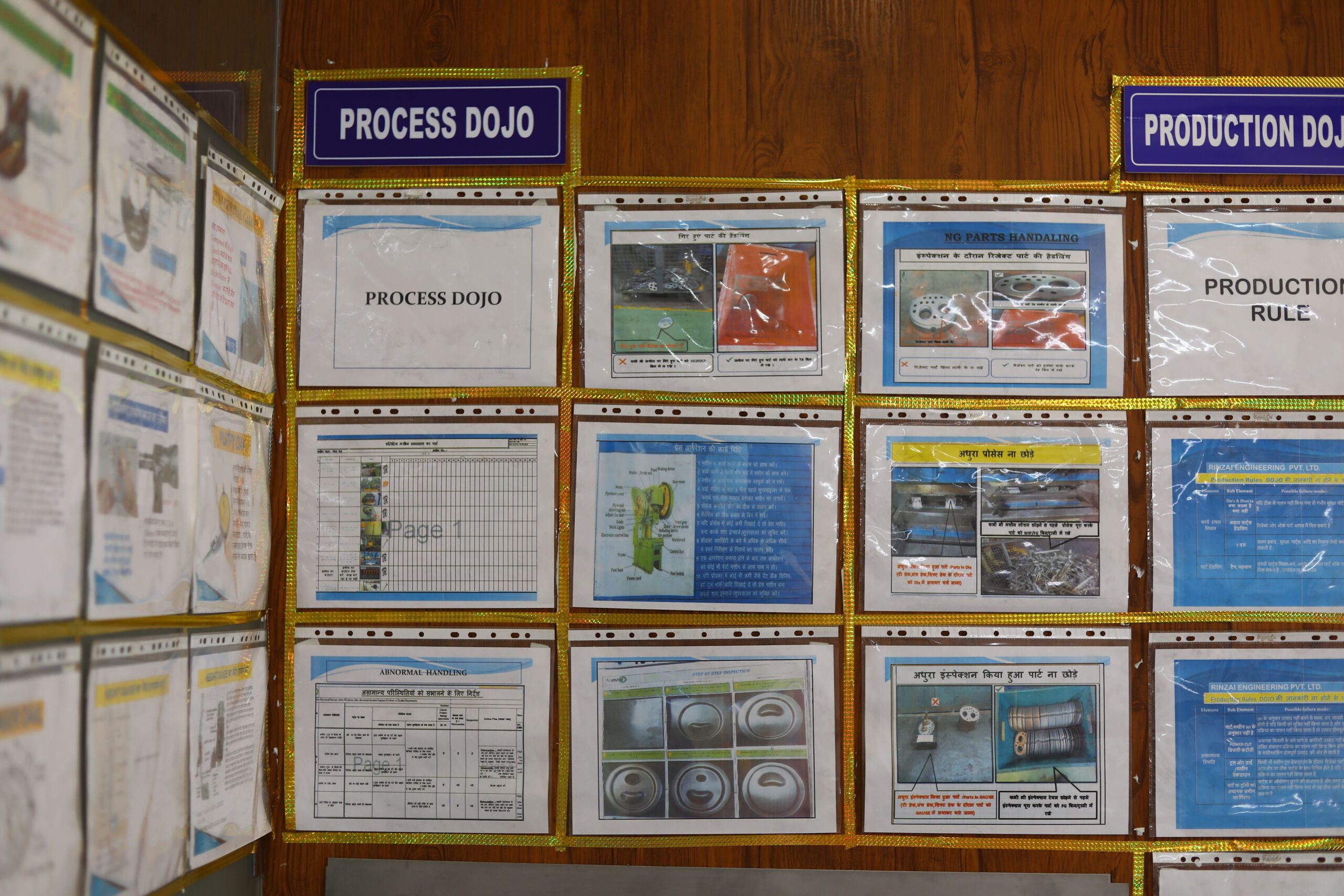

We place a strong emphasis on both the production method and the basic material when it comes to being picky about quality across the board in our product line. We have developed a zero-error quality policy that aligns with manufacturing procedures in order to determine the quality. We can quickly and automatically identify, recognize, and fix any defects and limitations thanks to our direct interaction with production equipment.

4 Wheeler Parts Manufacturer